Scientists have evolved HydroSpread, a novel technique for building soft robots on water, with wide-ranging possibilities in robotics, healthcare, and environmental monitoring.

Picture a miniature robot, no large than a leaf, gliding effortlessly throughout the surface of a pond, much like a water strider. In the future, machines of this scale will be deployed to monitor pollution, gather water samples, or explore flooded zones too unsafe for people.

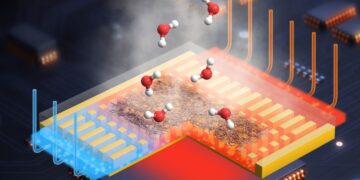

At the University of Virginia’s School of Engineering and Applied Science, mechanical and aerospace engineering professor Baoxing Xu is operating on a way to make such devices a reality. His group’s recent study, published in Science Advances, discloses HydroSpread, a fabrication process unlike any earlier than it. The approach allows researchers to create soft, buoyant machines directly on water, a breakthrough forward with applications that might range from medical care to purchaser electronics to environmental monitoring.

Earlier, generating the thin and bendy films important for soft robotics needed building them on solid surfaces inclusive of glass. The fragile layers then needed to be lifted off and located onto water, a tricky process that often led to tearing and material loss.

HydroSpread sidesteps this trouble by letting liquid itself serve as the “workbench.” Droplets of liquid polymer ought to naturally spread into ultrathin, uniform sheets on the water’s surface. With a finely tuned laser, Xu’s group can then carve these sheets into complicated patterns — circles, strips, even the UVA logo — with remarkable precision.

From Films to Moving Machines

Using this approach, the researchers constructed two insect-like prototypes:

- HydroFlexor, which paddles throughout the surface the usage of fin-like motions.

- HydroBuckler, which “walks” ahead with buckling legs, stimulated by water striders.

In the lab, the group powered these gadgets with an overhead infrared heater. As the films warmed, their layered structure bent or buckled, creating paddling or walking motions. By cycling the heat on and off, the devices could modify their speed and even turn — evidence that controlled, repeatable movement is feasible. Future variations could be designed to reply to sunlight, magnetic fields, or tiny embedded heaters, opening the door to autonomous soft robots which could move and adapt on their own.

“Fabricating the film directly on liquid gives us an exceptional level of integration and precision,” Xu stated. “Instead of constructing on a rigid surface after which transferring the device, we permit the liquid do the work to offer a perfectly smooth platform, reducing failure at each step.”

The potential reaches beyond soft robots. By making it easier to form sensitive films without damaging them, HydroSpread could open new possibilities for creating wearable medical sensors, flexible electronics, and environmental monitors units — tools that need to be thin, soft and durable in settings wherein traditional inflexible materials don’t work.