Engineers have advanced a passive evaporative cooling membrane that considerably improves heat removal for electronics and data centers

Engineers on the University of California San Diego have formed an innovative cooling system designed to substantially improve the energy efficiency of data facilities and high-overall performance electronic devices. This new technique is depends on a specifically engineered fiber membrane that naturally gets rid of heat through evaporation. It gives an impactful and energy-saving options to conventional cooling techniques which include fans, heat sinks, and liquid pumps, while also doubtlessly decreasing the large amounts of water used by many existing systems.

The breakthrough is explained in detail in a study at published within the journal Joule.

As artificial intelligence (AI) and cloud computing continue to develop, so does the requirement for data processing, and the heat that follows it. Cooling now represents as an much 40% of a data center’s total energy intake. If latest development maintains, worldwide energy require for cooling could more than double by 2030.

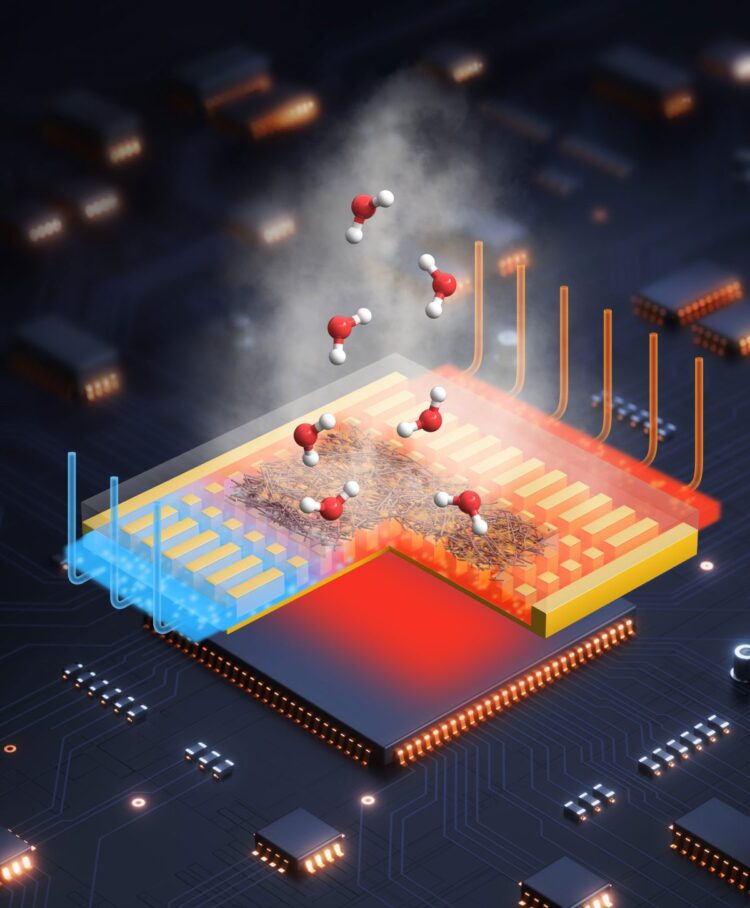

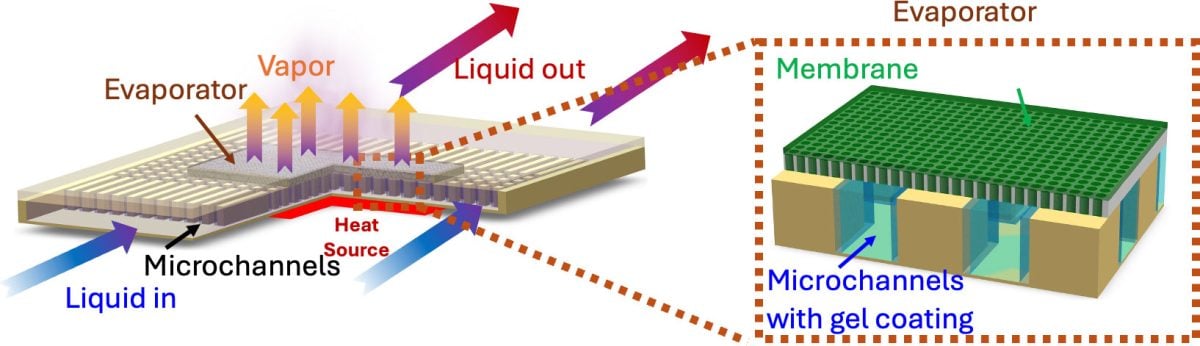

The recently advanced evaporative cooling system might also support slow this trend. It operates using of an cost-effective fiber membrane made of limitless interconnected microscopic pores that draw cooling liquid throughout its surface by capillary action. When the liquid evaporates, it gets rid of heat from the basic electronics without the need for additional energy. The membrane is positioned above microchannels that supply the liquid, permitting heat to dissipate efficaciously from the components below.

Illustration of the fiber membrane pulling liquid from microchannels into its pores through capillary action and cooling a heat source as the liquid evaporates. Photo Credit: https://scitechdaily.com/

Harnessing Evaporation for Efficient Heat Dissipation

“Compared to traditional air or liquid cooling, evaporation can expend higher heat flux at the same time as the using of less energy,” stated Renkun Chen, professor in the Department of Mechanical and Aerospace Engineering on the UC San Diego Jacobs School of Engineering, who co-led the venture with professors Shengqiang Cai and Abhishek Saha, both from the same department. Mechanical and aerospace engineering Ph.D. Scholar Tianshi Feng and postdoctoral researcher Yu Pei, both members of Chen’s research group, are co-first authors at the study.

Many programs lately depend upon evaporation for cooling. Heat pipes in laptops and evaporators in air conditioners are a few examples, defined Chen. But applying it successfully to high-strength electronics has been a challenge.

Earlier attempts using porous membranes—which have big surface regions best for evaporation—failed due to the fact the pores were often either too small, inflicting clogging, or too large, leading to unrequired boiling.

“Here, we use porous fiber membranes with interconnected pores with the right size,” stated Chen. This design obtained efficient evaporation without those downsides.

Record-Breaking Performance and Future Potential

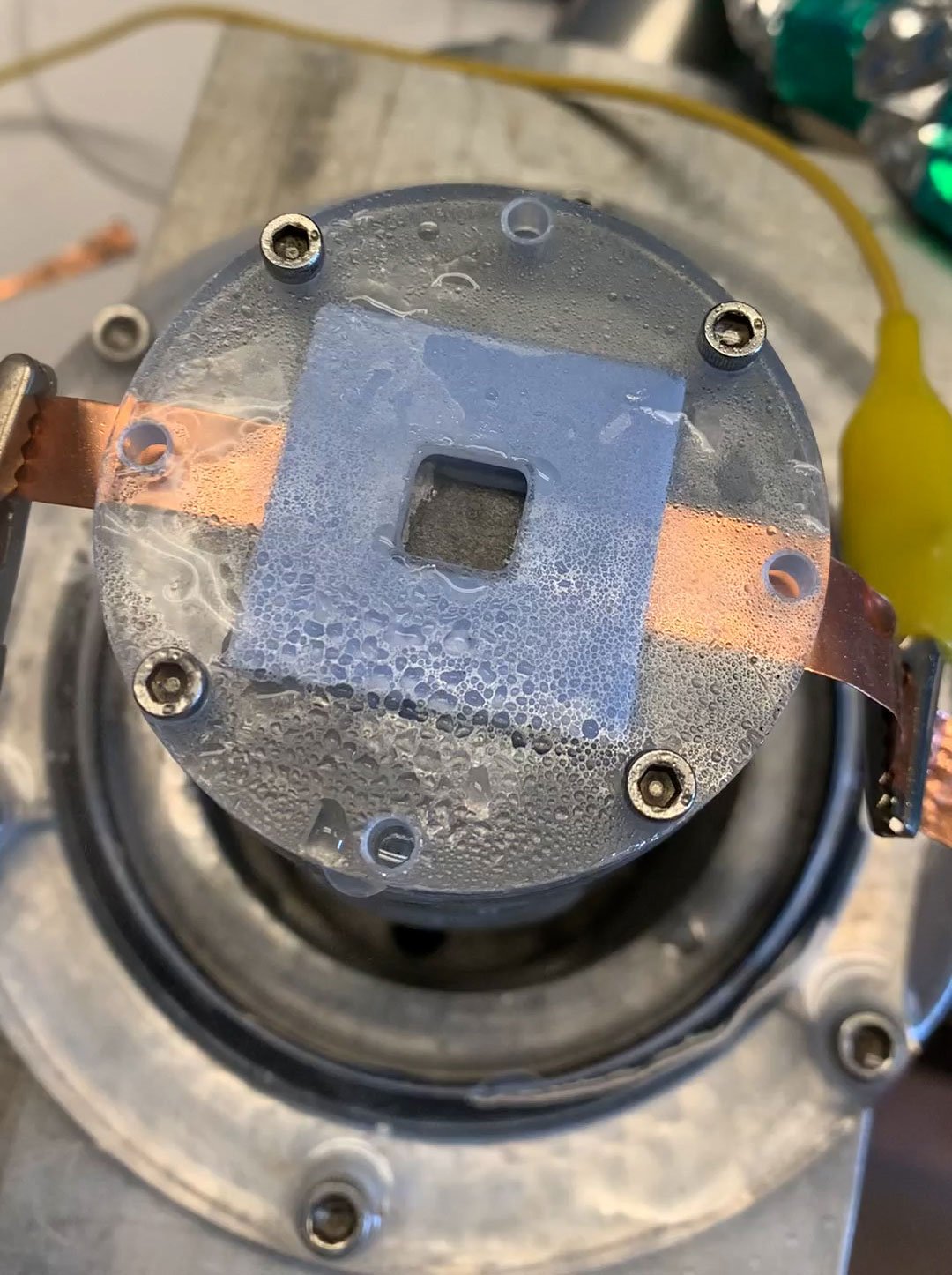

When tested throughout variable heat fluxes, the membrane obtained record-breaking performance. It controlled heat fluxes surpassing 800 watts of heat per square centimeter—one of the highest stages ever recorded for this form of cooling system. It also demonstrated stable over more than one hours of operation.

“This fulfillment presents the ability of reconsidering materials for totally new applications,” stated Chen. “These fiber membranes have been originally designed for filtration, and no one had earlier considered their use in evaporation. We recognized that their notable structural characteristics—interconnected pores and simply the right pore size—ought to make them ideal for efficient evaporative cooling. What surprised us was that, with the right mechanical reinforcement, they not simplest withstood the high heat flux–they executed extraordinarily well under it.”

While the present day outcomes are promising, Chen says the technology remains working well below its theoretical limit. The team is now working to refine the membrane and optimize overall performance. Next steps include incorporating it into prototypes of cold plates, which might be flat components that attach to chips like CPUs and GPUs to expend heat. The team is also launching a startup corporation to commercialize the technology.