An AI framework now computes once- impossible physics equations within seconds. The innovation redefines how scientists examine the behavior of materials.

Researchers at the University of New Mexico and Los Alamos National Laboratory have generated a advanced computational framework that solves a big problem that has challenged statistical physicists for decades.

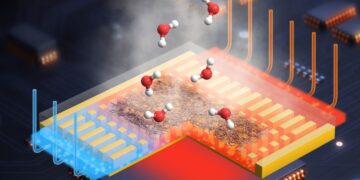

Known as the Tensors for High-dimensional Object Representation (THOR) AI framework, the system uses tensor network algorithms to efficiently compress and examine huge configurational integrals and partial differential equations. These equations are fundamental for figuring out how materials behave under different thermodynamic and mechanical conditions. By combining tensor networks with machine learning to know potentials, which represent interatomic forces and atomic motion, the researchers obtained correct, scalable simulations of materials throughout a huge range of physical environments.

“The configurational indispensable — which captures particle interactions — is notoriously difficult and time-taking to evaluate, mainly in materials science applications includes intense pressures or phase transitions,” stated Los Alamos senior AI scientist Boian Alexandrov, who led the venture. “Correctly determining the thermodynamic behavior deepens our scientific understanding of statistical mechanics and informs key regions which includes metallurgy.”

Overcoming the bounds of classical simulations

Historically, scientists have trusted approximate techniques like molecular dynamics and Monte Carlo simulations to estimate the configurational integral. These techniques indirectly mimic atomic motion over long term scales to work across the “curse of dimensionality,” in which computational complexity rises exponentially with every added variable, even overwhelming the world’s fastest supercomputers. Despite needs weeks of intensive processing, such simulations still gives restricted results.

Dimiter Petsev, a professor in the UNM Department of Chemical and Biological Engineering, regularly collaborates with Alexandrov on studies in material science. After learning about the brand new computational techniques Alexandrov’s team had advanced, Petsev found out they could be carried out to at solving the configurational integral—a task earlier appeared as impossible in statistical mechanics.

“Traditionally, solving the configurational necessary directly has been taken consideration impossible due to the fact the critical often includes dimensions on the order of thousands. Classical integration strategies could need computational times exceeding the age of the universe, regardless of modern computers,” Petsev stated. “Tensor method strategies, but, provide a new standard of accuracy and performance against which different tactics can be benchmarked.”

Fast and accurate computation with THOR AI

THOR AI transforms this high-dimensional challenge into a tractable problem via representing the high-dimensional data cube of the integrand as a series of smaller, related components using a mathematical technique referred to as “tensor train pass interpolation.” A custom variant of this technique identifies the essential crystal symmetries, allowing the configurational vital to be computed in seconds in preference to thousands of hours — without loss of accuracy.

Applied to metals which includes copper and noble gases at high strain, like argon in crystalline state, as well as to the calculation of tin’s solid-solid section transition, THOR AI reproduces consequences from the best Los Alamos simulations — however more than 400 times rapid. It also works seamlessly with modern machine learning- based atomic models, making it a flexible tool for materials science, physics, and chemistry.

“This innovation replaces century-old simulations and approximations of configurational necessary with a first-principles calculation,” stated Duc Truong, Los Alamos scientist and lead author of the study published in Physical Review Materials. “THOR AI opens the door to faster discoveries and a deeper understanding of materials.”